I have touched before on Peridot’s reputation as experts in micro-machining. In the last couple of years as we continue to acquire and place into service larger CNC machines we can now demonstrate expertise in considerably larger parts. I will present a few here for your consideration.

Our first example:

Part Name: Corona Guard Upper

Description: CNC turned plate with secondary milling operations

Material: 316 stainless with Titanium nitride coating and laser marking

Next up it the previous part’s companion in the assembly.

Part Name: Corona Guard Lower

Description: CNC turned plate with secondary milling operations

Material: 316 stainless with Titanium nitride coating and laser marking

Next is a cover for an aerospace electronics assembly.

Part Name: Cover plate, top

Description: CNC milled cover plate

Material: 5052 H32 Aluminum

Again followed by it’s companion part in the assembly

Part Name: Cover Plate, bottom

Description: CNC milled cover plate

Material: 5052 H32 Aluminum

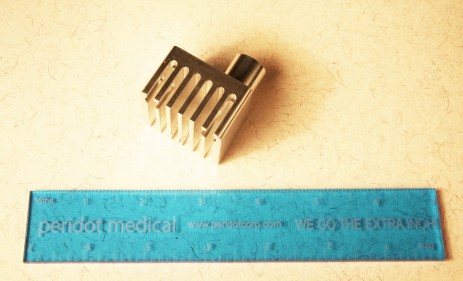

Next in the series is an aluminum heat sink for a network router.

Part Name: Heat Sink

Description: CNC Milled fins and turned mount

Material: 6061 T6 Aluminum

As discussed in a previous blog post, Peridot excels at CNC machining of plastics. This is often far easier than machining some of the high performance materials such as Inconel and Hastalloy. Our next example:

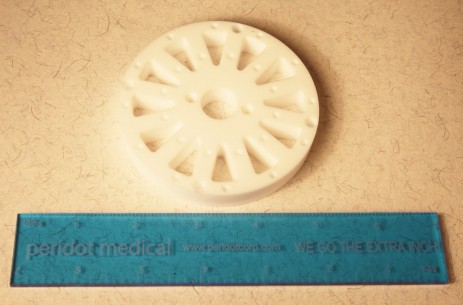

Part Name: Indexer Plate

Description: CNC Turned/milled complete on mill/turn center

Material: White Nylon

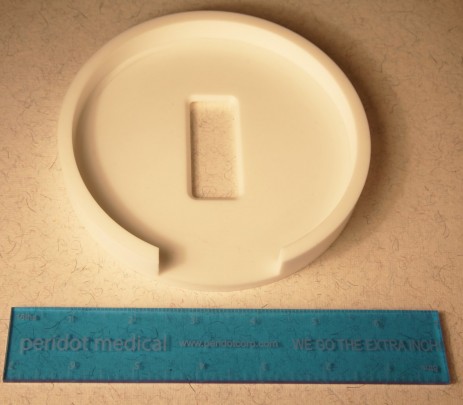

Another example of machined Nylon.

Part Name: Aperture Indexer

Description: CNC Turned/Milled on Mill/Turn center

Material: White Nylon

Shifting gears here to an assembly used in a Spinal procedure. Lots of swoopy 3D curves on this one!

Part Name: Assembly,Jacking

Description: CNC milled 6 piece assembly

Material: Heat Treated and Bead Blasted 420 stainless

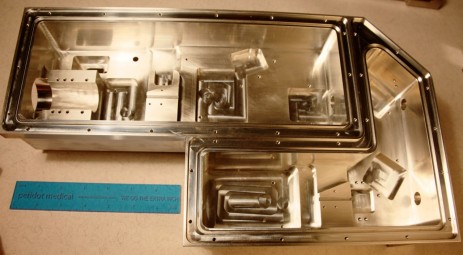

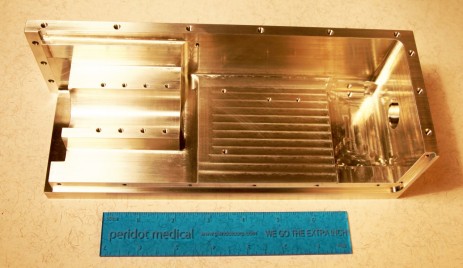

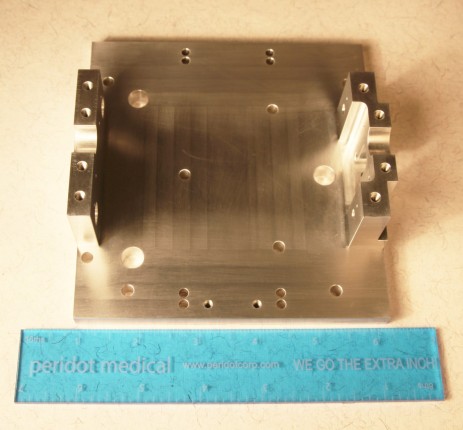

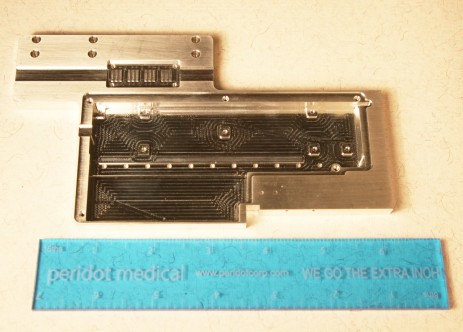

The final 3 parts in this series are all Optics Platforms for a laser resonator cavity. These all have extraordinarily tight tolerances for parallelism and perpendicularity as alignment in this application is critical to functionality.

Part Name: Laser Resonator Cavity Optics Platform

Description: CNC milled on dual pallet Horizontal mill

Material: 6061 T6 Aluminum

As you can see Peridot has significantly expanded our machining capabilities by making substantial investments in new state-of-the-art multi-axis machines. We hope you take advantage of this capability!